|

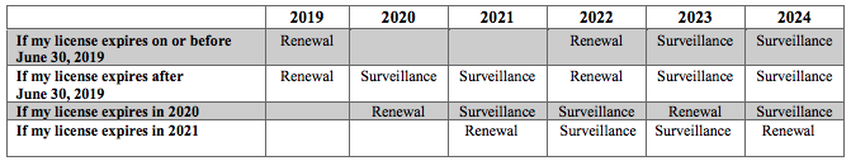

Is your API-Certified Facility affected by the new Monogram Program Auditing update? Previously, facilities were able to apply for a Monogram License only and a re-certification audit would occur every three years if the company did not apply for a quality registration (ISO 9001, API Q1, API Q2, ISO 14001, or OHSAS 18001). The facility still had to meet the requirements of API Q1 as required by the Monogram Program but would not be audited every year, saving in audit costs by API. Things have changed. As industry leaders demand more consistent products and stricter surveillance programs on manufacturers, API and its standards committees have answered the call by implementing annual audits for all facilities under their licensing programs. What does this mean for your facility? Only those with a Monogram Licenses that are not registered with a quality standard will be affected. This also depends on where the license expiration falls in the calendar year. If your Monogram License expires on or before June 30th, 2019, the annual audits will not begin until 2022. If your license expires after June 30th, 2019, the rule will go into effect immediately. If your license expires in 2020, the annual audits will begin after the renewal audit that same year and the same rule applies in the year 2021. Here is a chart to assist with determining what audit cycle your facility may fall under: How to prepare This new program change will mean more accountability from the industry and more pressure to maintain a quality program throughout the lifecycle of the certification. In times past, a majority of facilities with only a Monogram License that were audited every 3 years failed their audit and were required to be re-audited by API. Not only did this result in further audit costs, but also a suspension of the license during the long process of scheduling a re-audit and determining if responses to non-conformances met the expectations and requirements of the program. Facilities will now have to maintain their programs every year. In theory, this was supposed to occur and companies should have maintained compliance with API Q1 at all times when they possessed an active Monogram License. In reality, many quality management system fell apart during this three-year time period and were only held accountable by either a surprise API audit or industry peers filing complaints about product non-conformances. Now that annual audits will be conducted for all API-licensed and registered facilities, companies will need to be in regular preparedness for an API Audit or face the consequences of a suspension or worse, a canceled license and the long process of reapplying. Yes, this is a positive step for the Oil & Gas industry but it’s going to require more attention and costs to maintain quality and product licenses. Click for the official API Announcement LetterCLICK for more information about Capstone Quality Services, LLC and to set up a free consultation on how our services can help your company achieve its certification objectives.

0 Comments

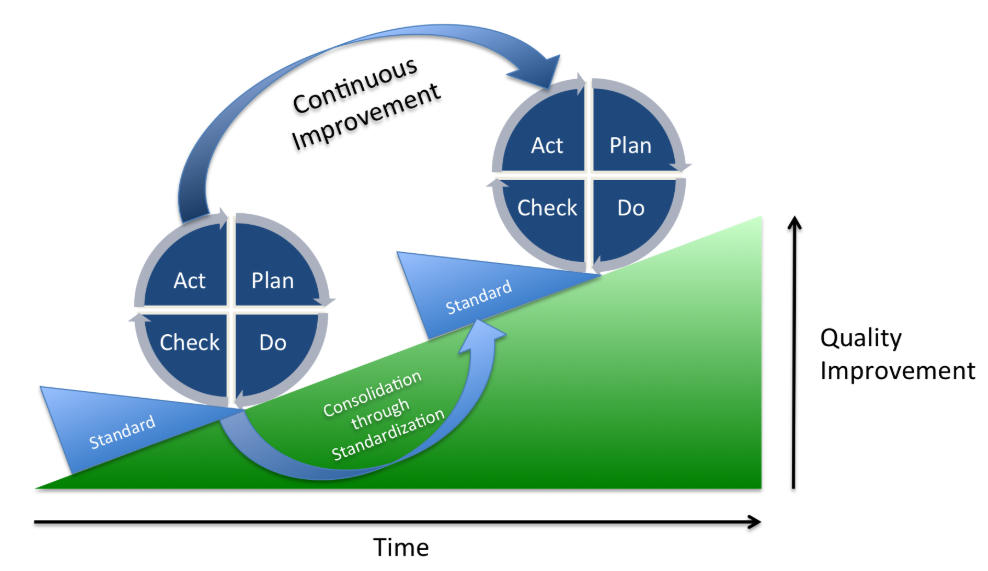

ISO 9001 is the world's most recognized management system standards and is currently being used by over a million companies and organizations throughout the world. This standard provides guidance and tools for organizations to ensure that their products and services consistently meet customer’s requirements and that quality is consistently improved over time. Regardless of size, industry, or language this standard can be followed in order to improve the management system structure and ensure deliverability of product or service to customers. This standard is based on many quality management principles including the continual improvement, process approach, motivation and implication of top management and customer-driven focus. Throughout this guide, we will walk you through various sections of ISO 9001 to compare and contrast the new 2015 edition in order to better your understanding of how to prepare your system for your next audit. Benefits of ISO 9001 Quality Management

ISO 9001-2015 transition outline

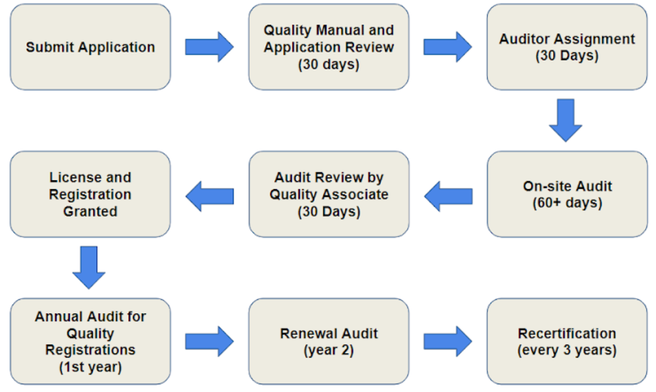

Where do I begin? Should I hire a consultant? Do I have the time and resources to get my facility certified? How much money will this process take? These are just a few questions that most quality managers and owners ask themselves when deciding on a quality management system standard for their business. This can be a confusing and difficult time for anyone in leadership. Often, this seemingly monumental task leads to inaction on what could be a great business opportunity. Throughout these steps and available resources listed below, I will explain the process of how your oil & gas company can become certified with the American Petroleum Institute to API Q1, API Q2, ISO 9001: 2015, OHSAS 18001, ISO 14001, API Std 18LCM (API Standard 18 for Life-Cycle Management) or an API Monogram product license. Within this guide, you will understand the proper documentation, pricing, and resources to get your organization certified with the most prestigious oil & gas certification body in the world.

Taking part in the American Petroleum Institute’s Certification Program is one of the most important steps in elevating your oil & gas business to the next level of quality by placing your company on the world stage via the API Composite List. Currently, there are nearly 5000 certified facilities in over 80 countries worldwide belonging to both the API Monogram and American Petroleum Institute Quality Registrar (APIQR) programs. These companies range from small mom-and-pop shops to large, multinational corporations. While the process is long and seemingly unending, it is entirely possible to become one of these prestigious companies by following this guide. Questions to Consider Before ApplyingThe American Petroleum Institute covers many types of standards for specific oil & gas equipment and quality registrations of varying management systems. It is important to understand these categories and how they can help your company when making the decision to apply. Here are a few questions to consider:

Not only will an API Certification assist your company with global recognition and opportunities in expanding to other markets, these standards are powerful tools in organizing your manufacturing productivity. It may seem like more paperwork but quality management systems can be written in a meaningful and easy-to-use manner that is both beneficial to your company and your customers alike. Prerequisites to ApplyingListed below are important prerequisites to implement and follow before applying for a certification with API. Timelines are an important component to consider when applying for certification because of audit scheduling and the extra work when implementing a quality system within your business.

Quality Consultants for the Oil & Gas Industry |

Archives |

Capstone Quality Services, LLC

1707 Post Oak Boulevard 1/2 #614

Houston, TX 77056

281-500-9665

1707 Post Oak Boulevard 1/2 #614

Houston, TX 77056

281-500-9665

RSS Feed

RSS Feed